- Oil Seal 14x22x5 A Comprehensive Guide

Cover the valve gear with a clean cloth to prevent dirt getting into the working parts of the engine.

• Rubber torque prevents gear rattling noise

Housing bore number - Crafted from durable rubber materials, this gasket is designed to provide an airtight and watertight seal around pipes, fixtures, and other components where a 1-inch diameter opening is present. Its elasticity allows it to conform to the shape of the objects it interfaces with, ensuring a snug fit that prevents leaks and maintains pressure.

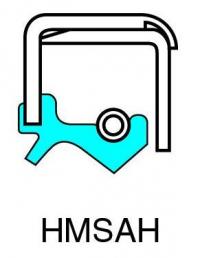

- There are several types of metal-to-oil seals available on the market, each with its unique design and application. Some of the most common types include

What are Oil Seals and the different types?

3. Dust and debris are common reasons for oil seal failure.

- Motor oil seals play a crucial role in preventing leakage of oil from the engine. These seals are designed to keep the oil sealed within the engine, preventing it from leaking out onto the ground or other components of the vehicle.

The shaft on which the oil seal is mounted has to be ground to a rough surface finish. The shaft also should be hardened to prevent grooves forming on the shaft when the pressure is exerted by the spring on the seal. The area where the seal is fitted also has to be ground to prevent grooves that tend to wear out the lip of the oil seal faster than normal.

Double metal cased

12 22 5 oil seal. Its ability to resist wear and tear ensures that machinery stays operational for longer periods without the need for frequent maintenance.

oil seal 50 * 72 * 10.

Before installing the oil seal, check the seal carefully for damage. Make sure there are no cuts or tears around the seal lip, which is the two layers inside the oil seal.

Another thing to consider is the outer diameter of the oil seal. Any damage detected prior to installation will make it impossible to use further.

Oil seals, also referred to as shaft seals, are widely used to prevent the leakage of medium (such as oils and grease) along a rotating shaft. This leak prevention is primarily achieved by the sealing element which can be made from a wide range of materials that are chosen according to each application. They are commonly used in gearboxes, hydraulic cylinders, and related components.

20 35 7 oil seal. A properly selected and installed oil seal can significantly improve the performance and reliability of the equipment, reducing maintenance costs and downtime.

Exhaust gaskets prevent toxic fumes from escaping the system, while radiator gaskets prevent coolant loss, both contributing to the overall efficiency and safety of the vehicle Exhaust gaskets prevent toxic fumes from escaping the system, while radiator gaskets prevent coolant loss, both contributing to the overall efficiency and safety of the vehicle

Exhaust gaskets prevent toxic fumes from escaping the system, while radiator gaskets prevent coolant loss, both contributing to the overall efficiency and safety of the vehicle Exhaust gaskets prevent toxic fumes from escaping the system, while radiator gaskets prevent coolant loss, both contributing to the overall efficiency and safety of the vehicle gasket auto.

gasket auto.BS

With minor lip

Type code

Table 2 b): Common types of oil seals (without spring)

If the drive gear has slanting teeth, they may cause the rotor arm to turn. If it does, mark its new position to aid refitting

A